|

<< Click to Display Table of Contents >> Load Transfer |

|

|

<< Click to Display Table of Contents >> Load Transfer |

|

Load transfer C can be through aggregate interlock or through dowels and steel bars.

With aggregate interlock the crack width and the roughness within the crack plays a role. Where steel is used, the steel diameter as well as the stiffness of the concrete around the steel affects the success of load transfer with time. In both cases load transfer can be expected to decrease with time as a result of fatigue or wear out of concrete and aggregate.

The aggregate size Agg can be taken as the nominal size of the 15 % largest aggregate ie the theoretical sieve size through which 85 % of the aggregate will pass. The value should be between 12 mm for a thin continuously reinforced slab and 50 mm for a thick jointed slab. If the joint is not a contraction joint but a keyed joint, take aggregate size of 17 mm as input.

The crack width Dx that develops in the joints (cracks in the case of continuously reinforced concrete) is due to shrinkage and the environment (temperature changes and humidity). The crack width can be calculated from the spacing between joints/cracks times 0.00055 as a first approximation.

The relative vertical movement Dy at a joint/crack under wheel loads is associated with the looseness of steel bars or erosion of aggregate with time. Practical measurements in the field have indicated average values of 0.30 mm for jointed pavement, 0.15 mm for doweled pavement and 0.10 mm for continuously reinforced concrete (CR), after these pavements have been in use for some years.

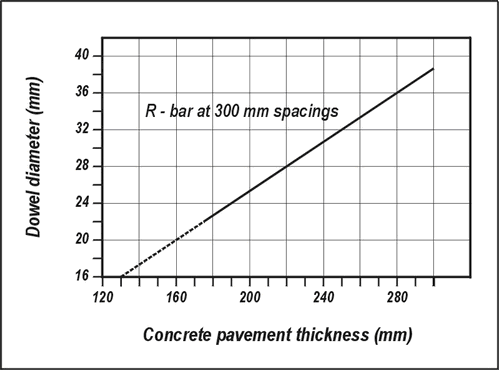

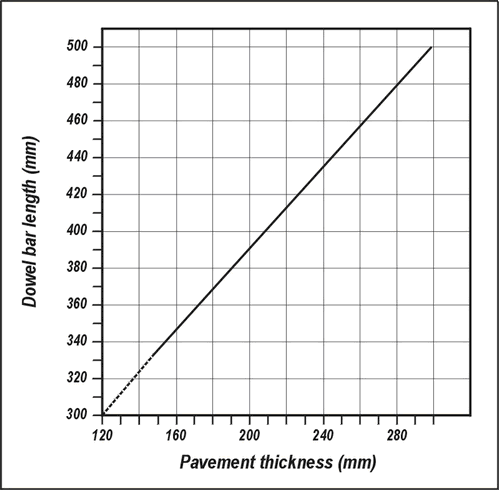

Steel spacing for dowel bars is normally 300 mm and a 32 mm steel diameter is used for doweled concrete pavements between 215 mm and 250 mm thick, and 25 mm bars for pavements thinner than 215 mm, see the two figures below. For continuously reinforced concrete pavements a steel diameter of 16 mm high tensile strength bars is normally used, at about 220 mm steel spacing for 150 mm thick slabs, and at about 150 mm spacing for 220 mm thick slabs. However this depends on the required crack spacing. For ultra-thin continuously reinforced concrete pavements a steel diameter of 5.6 mm is normally used, with a spacing of 50 mm both transversely and longitudinally.

The load on the steel Pd can be calculated from the following:

Load Pd = K.P. spacing

where

P wheel load in kN

K 0.0003 for pavement with concrete shoulder, or 0.0004 for pavement without concrete shoulder,

and spacing is the spacing of steel in mm.

In the design procedure the load transfer factor C is considered to be a function of relative vertical movement that occurs at a crack or joint when a load is applied on one slab at the joint/crack.

C = function (Dy)0.5

where

Dy relative vertical movement at a joint or crack.