|

<< Click to Display Table of Contents >> Axle Loads |

|

|

<< Click to Display Table of Contents >> Axle Loads |

|

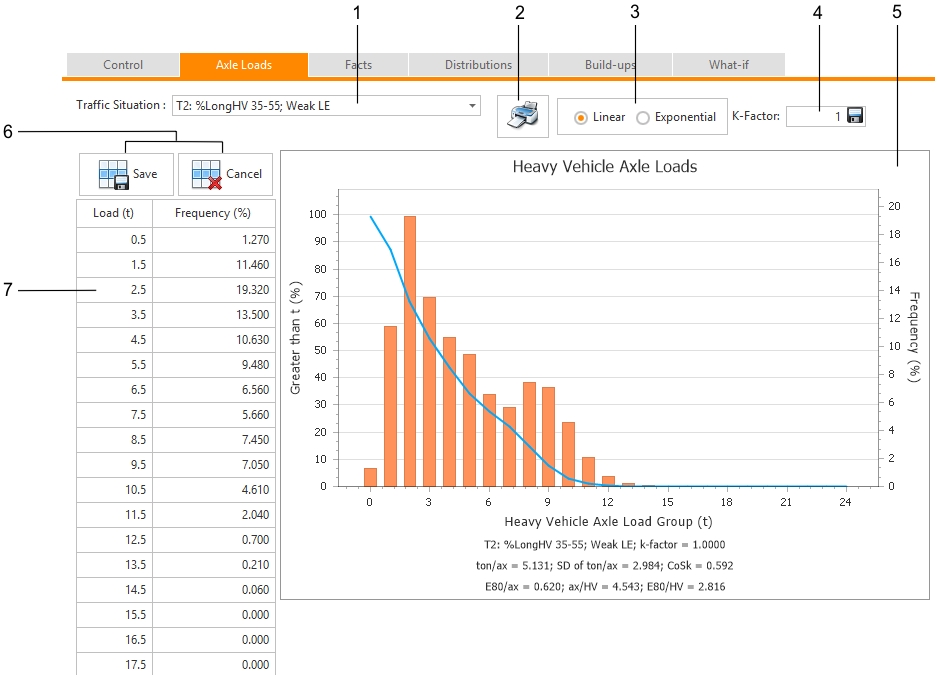

The Axle Loads Page is the second of two input pages (the first one is the Control Page). This page is illustrated below:

At point 2, a selection of Traffic Situations are found.

Typical axle load distributions are available for the following traffic situations :

•T1: %Long HV < 35; (Any LE)

•T2: %LongHV 35-55; Weak LE

•T3: %LongHV 35-55; Strong LE

•T4: %LongHV > 55; Weak LE

•T5: %Long HV > 55; Strong LE

•Streets in heavy-industry areas

•Streets in light-industry areas

•Residential streets

•Heavy-truck standing areas

•Light-truck standing areas

•One single axle load

•Other traffic situation

T1, T2, T3, T4 and T5 are abbreviations for the five basic traffic models. Traffic models are defined in terms of the percentage of long heavy vehicles, %Long HV, and the intensity of law enforcement against overloading, LE (Ref. 10). Long truck (long HV) is typically a three-chassis combination, whose length exceeds 18 m, such as the so-called interlink, consisting of a truck tractor, a semi-trailer, and yet another semi-trailer at the end. The percentage of these vehicles is known from ordinary traffic counts that are done by means of inductive loops. Should only the percentage of heavy vehicles be known then assume that the %Long HV is in the 35 % - 55 % region. Strong law enforcement implies a permanent and continuously operated weighbridge in the vicinity, or another systematic and effective overloading-control strategy in the area. Weak law enforcement means sporadic and ad-hoc traffic police actions using portable scales, other occasional spot-checks on overloading, or nothing at all.

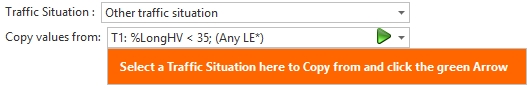

For a selected Traffic Situation, the Axle Load Distribution is given in the table at point 8. The Frequencies of the Axle Load Distribution cannot be changed except for the Traffic Situation named Other traffic situation. If a user attempts to change the frequencies and if Other traffic situation is not selected, cncPAVE will warn the user that the frequencies cannot be changed, but will also ask the user if cncPAVE should select Other traffic situation on the user's behalf. If the user clicks OK, cncPAVE will select Other traffic situation and the following will happen:

• A second drop-down list will appear with a list of Traffic Situations ("Copy values from")

• An orange pop-up notifier will appear to indicate that values could be copied from this list of Traffic Situations

This is illustrated below:

When the user chooses a traffic situation the typical average number of axles per HV is automatically supplied by the system and appears as constant no. 3 on the Control Page (where it can be edited by the user).

For Other traffic situation, one can select a Traffic Situation to copy values from. Once selected, the green arrow button next to the list should be clicked. The values from that selected Traffic Situation will be copied to the table for Other traffic situation. It will also be possible now to modify the frequencies of the Axle Load Distribution. Each cell for a changed frequency will turn to green. The user can change multiple frequencies and then click the Save button to save all changes together or the Cancel button to cancel all frequencies entered. This is a similar approach as found under Control.

It is important to recap on the following: For Frequencies that can be changed, a user can change multiple cells without saving it to the database. Unsaved cells will be green. Once the user is satisfied, all changes are committed at the same time by clicking the Save button. All cells will now be white. If the Cancel button is clicked, then all changes made since it last was saved will be lost! It is important to save changes before running the calculation process or moving to another section for cncPAVE to operate as it should! Please note that there are two sets of Save and Cancel buttons - one set at the top and one set at the bottom of each table. This is just to make it easier to locate these buttons.

The numbers in the Load (t) column are the so-called mid-group values. A mid-group value represents all axle loads in the interval starting exactly half-way between this mid-group value and the one below, and ending exactly half-way between this mid-group value and the one above; for example the mid-group value of 8.5 t represents all the axle loads between 8 t and 9 t.

The Axle Load Chart at point 5 will be updated automatically as information is changed. A de-cumulative ('greater-than') distribution of axle loads represented by the thick descending blue curve is also shown in the chart. You may wish to use this curve to determine the probability of an axle load exceeding a certain value, say, 9.5 tons.

Main traffic characteristics, such as

•average t/axle,

•standard deviation of t/axle,

•the coefficient of skewness of the axle-load distribution (CoSk),

•E80/axle,

•axles/HV, and

•E80/HV

are calculated and shown below the graph. The coefficient of skewness, CoSk, is a statistic measuring the lack of symmetry in a distribution; if a distribution is symmetric CoSk = 0. Distributions with a long tail on the right have a positive CoSk. When the long tail is on the left, i.e. in the low-value region, then CoSk is negative.

To export this chart, click the Print button at point 2. The following menu will appear:

It is possible to export the chart to either Adobe Pdf format or WMF. WMF is a vector format which means that it will not loose its quality when re-sized in Microsoft Word or other compatible applications. Select the desired format. Once selected, cncPAVE will export the chart as requested. Please note that this action will differ per Internet Browser.

Two Growth Models can be selected at point 3 namely:

• A linear traffic growth model.

• An exponential traffic growth model

To enter the k-factor, please enter the value at point 4 and click the save button next to the input box. Should you forget to save this value, cncPAVE will confirm if it should be saved once you attempt to work in another area in the system. The default value of this factor is 1.0. If you enter a different value, all axle loads are multiplied by the k-factor that you entered, the new distribution is plotted, and the new characteristics are shown below the graph. The permissible minimum and maximum values of the k-factor are 0.2 and 2.0, respectively. As a rule of thumb: Typically, increasing the k-factor from 1 to 1.05 (by 5 %) will increase the value of E80 by about 20%.

The k-factor facility may be appreciated by those who would like to benefit from the mechanistic design method, which is based on a distribution of axle-loads, but still wish to design for a certain amount of E80. This can be done by a trial-and-error as follows:

Enter a k-factor and click the Save button. Click the Run button under under the Control Page. After the run has been completed look at the total E80 shown in item no. 6 in the table on the right-hand side of the Facts Page. If the magnitude of the E80 is not correct return to the Axle Loads Page, change the k-factor and repeat the procedure until you obtain the desired total E80.

Should you wish to see the performance under axle loads of 80 KN each you can try to do the following:

1.Set the k-factor to 1.0.

2.Select Other traffic situation as a Traffic Situation and copy all values from One single axle load.

3.Enter 0 into the field for 6.5000 t,

4.enter 35 into the field for 7.5000 t and

5.enter 66 into the field for 8.5000 t.

6.Check that the value of E80/ax printed in the graph's footnote is 1.000.

7.Click the tab of the Control Page and run the program.

It is important to remember that all Axle Load data are stored per Scenario.

The Axle Load Chart will change and it will be necessary to run the calculation process when:

• A Traffic Situation is selected

• Axle Load Distribution Frequencies are changed

• The Traffic Growth Model is changed

• The k-factor is changed

Whenever some of these changes are made, cncPAVE will show a pop-up as illustrated below:

The reason for this notification is to remind the user that data changed and that the Calculation Button ![]() should be clicked under Control to perform calculations on the saved data. Calculations cannot be performed whenever data changes as this is a timeous process.

should be clicked under Control to perform calculations on the saved data. Calculations cannot be performed whenever data changes as this is a timeous process.